|

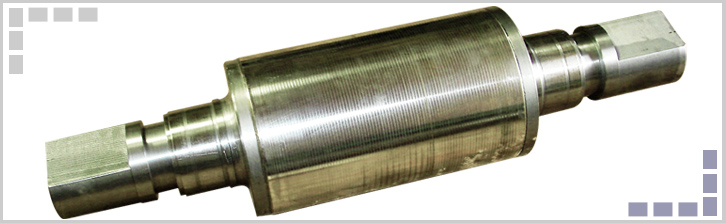

DOUBLE POUR CLEAR CHILL ROLLS(DPCC)

|

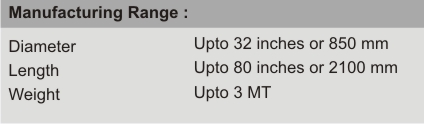

We produce double pour clear chill rolls by centrifugal casting. Which is an innovated casting method. With this casting the rolls remain free from Pin holes an cracks. The surface of these rolls gives uniform hardness and deep hardness, Which is indispensable for the high quality chill rolls. Its shell is predominantly made of Baintic or Mertensitic that has free Carbides and small quantities of Flake Graphite. This displays high abrasion and couple resistance properties to fire cracking. We have set benchmarks and have proved that the technique of using Alloys Chill for manufacturing Roughing Mills Stand is 25% more efficient than the S.G. Rolls, Alloy Steel Rolls and Adamite Rolls.

| |

| |

|

| |

| |

|

Application

Cold Steel Rolling Mills

Hot Steel Rolling Mills

Sugar Mills Shafts

Copper Rolling Mills

Plate Rolling

Automobile Stainless Steel Rolling

Agriculture Items |

|

| |

|

|

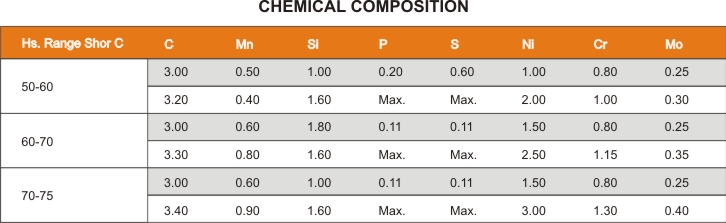

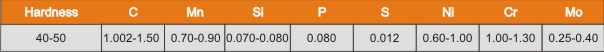

These rolls are special hyper-eutectoid steel rolls alloyed with Nickel, Chromium & Molybdenum. The extra carbon and special alloys give it extra wear resistance and strength These rolls are statically cast and undergo a special high temperature heat treatment process followed by tempering cycle to give a micro structure consisting of fine pearlitic martix with spherodised/ broken carbide. These rolls are suitable for rolling medium and heavy Sections where resistance is very important along with considerable amount of strength and toughness. These rolls are also used for roughing stand of Strip Mill.

|

|

|

|

| |

|

|

|